Our 201 Stainless Steel Sheet is a versatile, austenitic chromium-nickel-manganese alloy designed to offer an excellent balance of corrosion resistance, formability, and value. As a more economical alternative to 304 stainless steel, it provides reliable performance for a wide range of applications, particularly where high strength and excellent corrosion resistance are required in less aggressive environments. It is an ideal choice for manufacturers and builders seeking quality material without the premium cost.

Product Name | 201/201L Stainless steel plate |

Standard | JIS, AISI, ASTM, GB,DIN, EN, etc. |

Material | 201/201L |

Surface | black painted, anti rust varnished, PE coated, anti rust oiled, galvanized, checkered, color coated |

Width | 1219mm, 50mm-2200mm, or as customer's requirement |

Length | 2438mm, 3m, 5.8m, 6m, 11.8m, 12m, or as customer's requirement |

Thickness | Cold rolled:0.1~3.0mm or customer's requirement |

Technical Methods | Hot Rolled, Cold rolled |

Packing | Standard Seaworthy Packing, according to customer required |

MOQ | 1 Ton, more quantity price will be lower |

2. Key Features & Benefits

Excellent Cost-Efficiency: By utilizing manganese and nitrogen as partial substitutes for nickel, 201 stainless steel delivers remarkable mechanical properties at a more competitive price point than traditional 300-series alloys.

Good Corrosion Resistance: This alloy offers solid resistance to atmospheric corrosion, oxidation, and many organic and chemical chemicals. It is well-suited for environments that are not highly corrosive (e.g., interior applications, dry rural/urban atmospheres).

High Strength and Durability: 201 stainless steel exhibits higher yield strength and work-hardening rates compared to 304, making it exceptionally strong and damage-resistant, ideal for structural components.

Superior Formability and Weldability: The austenitic structure allows for easy fabrication, including bending, rolling, and drawing. It can be readily welded using all standard methods.

Attractive Aesthetic Appeal: It can be polished to a bright, smooth, and highly reflective surface finish, making it perfect for decorative applications, architectural trim, and consumer goods.

Easy Maintenance and Hygiene: The non-porous surface is easy to clean and sanitize, resisting staining and bacterial growth, which is crucial for food service and kitchen equipment.

3. Common Applications

Our 201 stainless steel sheets are widely used across various industries:

Architecture & Construction (Interior): Wall cladding, column covers, elevator doors, trim, and handrails.

Food & Beverage Industry: Sinks, kitchen equipment, shelving, and decorative elements for restaurants.

Automotive Industry: Trim, wheel covers, and exhaust systems.

Home Appliances: Dishwasher tubs, refrigerator panels, and range hoods.

Consumer Goods: Cookware, flatware, and decorative household items.

Storage Tanks and Containers: For specific non-harsh chemical contents.

4. Available Specifications

Standard: ASTM A240 / ASME SA240

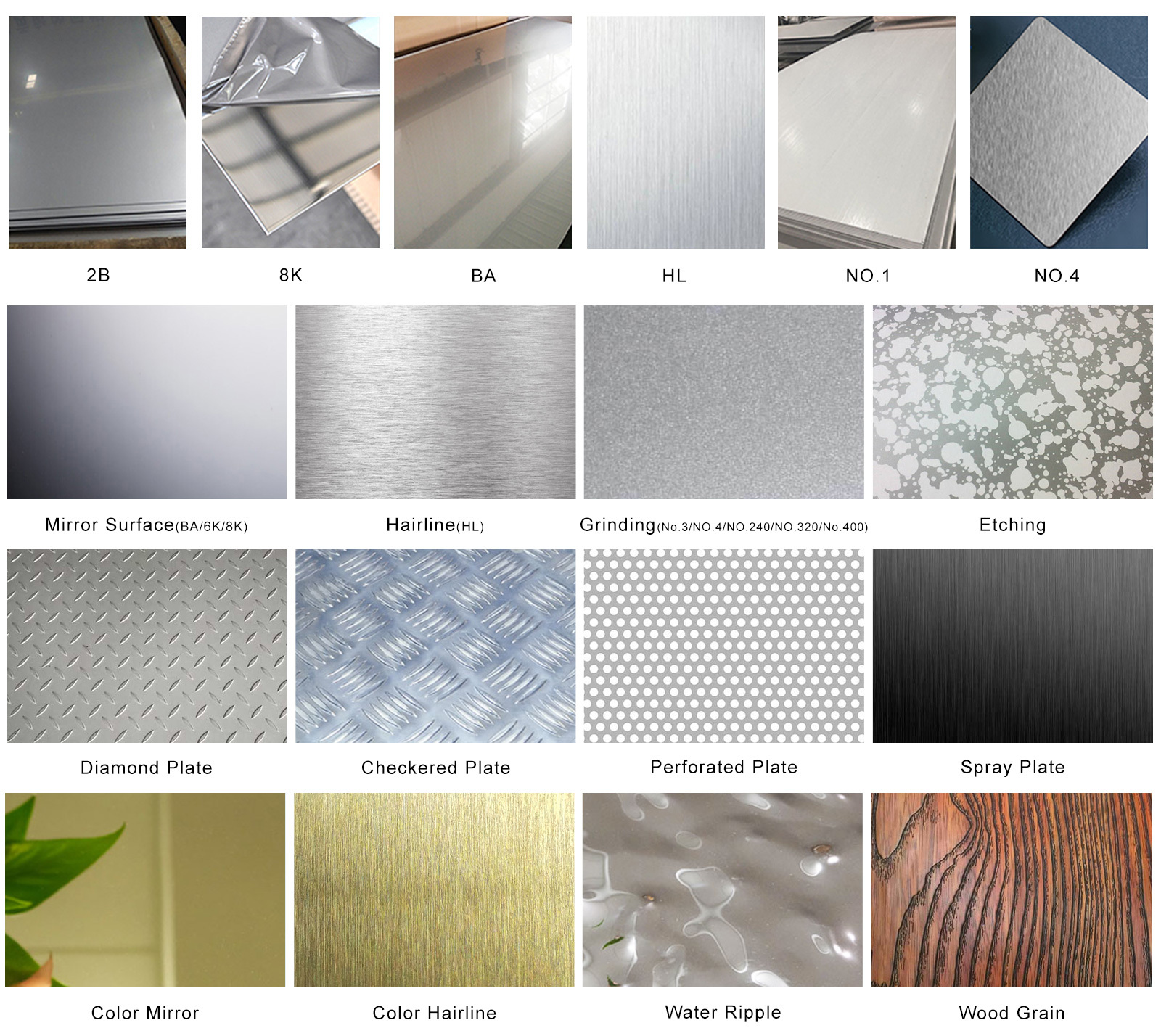

Surface Finish:

No. 1 (Hot-rolled, annealed, and pickled)

2B (Cold-rolled, bright annealed - most common)

No. 4 (Brushed finish)

BA (Bright Annealed - highly reflective)

8K Mirror Finish (Highly polished for decorative use)

Thickness: Ranging from 0.3mm to 6.0mm (Custom thickness available upon request)

Width: 1000mm, 1219mm, 1500mm (Standard), or custom widths.

Length: 2000mm, 2438mm, 3000mm (Standard), or custom lengths.

5. Technical Data (Typical Chemical Composition)

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 16.00 - 18.00 |

| Nickel (Ni) | 3.50 - 5.50 |

| Manganese (Mn) | 5.50 - 7.50 |

| Nitrogen (N) | ≤ 0.25 |

| Carbon (C) | ≤ 0.15 |

| Silicon (Si) | ≤ 0.75 |

| Phosphorus (P) | ≤ 0.06 |

| Sulfur (S) | ≤ 0.03 |

| Iron (Fe) | Balance |

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Sign up for our newsletter

Copyright © 2024 Shandong Ruixiang Iron and Steel Group Co., Ltd. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.