309S stainless steel is a high-alloy austenitic stainless steel specifically designed for extreme temperature applications. The low carbon content (denoted by the 'S' suffix) provides enhanced resistance to sensitization and subsequent intergranular corrosion, making it an ideal choice for prolonged exposure to elevated temperatures. Our 309S Stainless steel plates offer exceptional durability, strength, and resistance to oxidation, carburization, and sulfidation.

Product Name | |

Standard | JIS, AISI, ASTM, GB,DIN, EN, etc. |

Material | 309S |

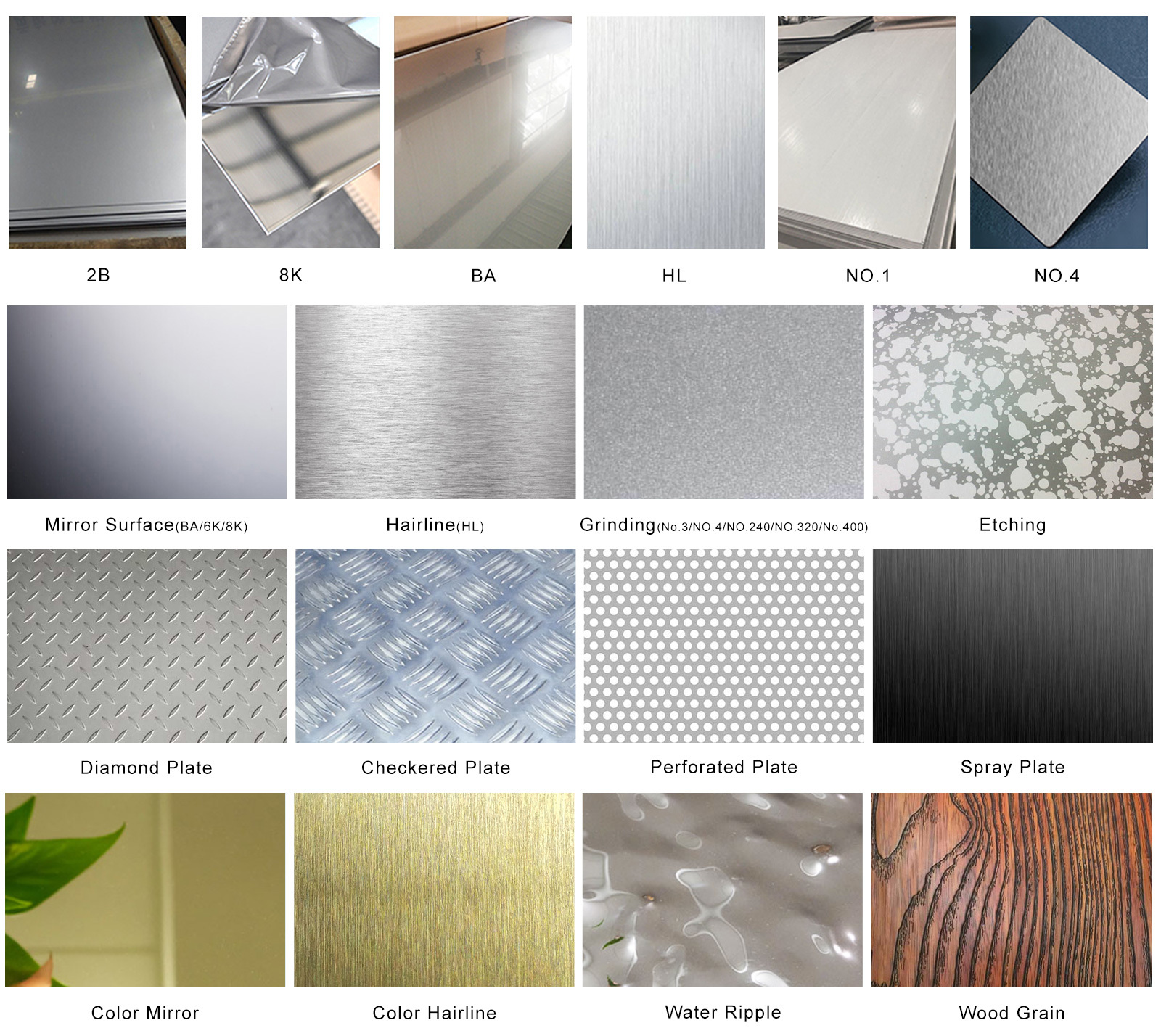

Surface | black painted, anti rust varnished, PE coated, anti rust oiled, galvanized, checkered, color coated |

Width | 1219mm, 50mm-2200mm, or as customer's requirement |

Length | 2438mm, 3m, 5.8m, 6m, 11.8m, 12m, or as customer's requirement |

Thickness | Cold rolled:0.1~3.0mm or customer's requirement |

Technical Methods | Hot Rolled, Cold rolled |

Packing | Standard Seaworthy Packing, according to customer required |

MOQ | 1 Ton, more quantity price will be lower |

Key Features & Benefits:

Excellent Oxidation Resistance: Outstanding resistance to scaling and spalling at temperatures up to 1150°C (2100°F), significantly higher than standard 304/316 grades.

Low Carbon Content (309S): The carbon content is controlled to a maximum of 0.08%, minimizing the precipitation of chromium carbides during welding and heating in the critical temperature range. This prevents intergranular corrosion and maintains corrosion integrity.

High Temperature Strength: Retains a high degree of mechanical strength and resistance to creep under load at elevated temperatures.

Good Corrosion Resistance: Offers superior corrosion resistance compared to 304/316 in a wider range of environments, particularly against sulfides and other aggressive compounds found in high-temperature industrial atmospheres.

Ease of Fabrication: Exhibits excellent formability and weldability using all standard fusion methods, both with and without filler metals.

Typical Chemical Composition (Weight %):

| Element | Carbon (C) | Chromium (Cr) | Nickel (Ni) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|

| % | 0.08 max | 22.0 - 24.0 | 12.0 - 15.0 | 2.00 max | 0.75 max | 0.045 max | 0.030 max | Balance |

Mechanical Properties (Room Temperature):

| Property | Tensile Strength | Yield Strength (0.2% Offset) | Elongation (% in 2") | Hardness (Brinell) |

|---|---|---|---|---|

| Value | ≥ 75 ksi (515 MPa) | ≥ 30 ksi (205 MPa) | ≥ 40% | ≤ 201 HB |

Note: Properties can vary based on plate thickness and heat treatment.

Common Applications:

309S plate is the material of choice for demanding high-heat environments, including:

Furnace Components: Radiant tubes, combustion chambers, muffles, retorts, and annealing covers.

Heat Exchangers & Boilers: For parts exposed to extremely high temperatures and corrosive gases.

Welding Consumables: Used as filler metal or electrode for welding dissimilar metals or for overlaying on carbon steel.

Chemical Processing Equipment: Components in petrochemical and fertilizer industries requiring heat and corrosion resistance.

Food Processing: Equipment like oven liners and parts in commercial baking and food processing.

Aircraft & Automotive: Exhaust systems, heat shields, and turbocharger components.

Available Specifications & Finishes:

Standards: ASTM A240, ASME SA-240

Thickness: Available in a wide range to meet your design requirements.

Width & Length: Custom cut to your specifications.

Surface Finish: Standard 2B, No. 1, No. 4, BA, or as required.

Why Choose Our 309S Plates?

We provide premium-quality 309S stainless steel plates that undergo rigorous quality control to ensure they meet the highest international standards. Our products are traceable and come with full Mill Test Certifications (MTC/EN 10204 3.1). We offer competitive pricing and reliable global logistics to get you the material you need, when you need it.

Contact Us Today:

For a quotation, technical data sheet, or to discuss your specific application requirements, please contact our sales team. Let us provide you with the high-performance material solution that ensures the longevity and reliability of your high-temperature equipment.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Sign up for our newsletter

Copyright © 2024 Shandong Ruixiang Iron and Steel Group Co., Ltd. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.