321 Stainless steel plate is a titanium-stabilized austenitic chromium-nickel stainless steel. The addition of titanium, which is a strong carbide former, makes this alloy exceptionally resistant to sensitization and subsequent intergranular corrosion. This is specifically beneficial when the material is exposed to temperatures in the chromium carbide precipitation range (800°F - 1500°F / 427°C - 816°C). 321 plates are the ideal choice for high-temperature service and offer excellent corrosion resistance, formability, and weldability.

Product Name | |

Standard | JIS, AISI, ASTM, GB,DIN, EN, etc. |

Material | 321 |

Surface | black painted, anti rust varnished, PE coated, anti rust oiled, galvanized, checkered, color coated |

Width | 1219mm, 50mm-2200mm, or as customer's requirement |

Length | 2438mm, 3m, 5.8m, 6m, 11.8m, 12m, or as customer's requirement |

Thickness | Cold rolled:0.1~3.0mm or customer's requirement |

Technical Methods | Hot Rolled, Cold rolled |

Packing | Standard Seaworthy Packing, according to customer required |

MOQ | 1 Ton, more quantity price will be lower |

Key Features & Advantages

Exceptional High-Temperature Strength: Maintains superior mechanical properties and oxidation resistance at elevated temperatures, making it perfect for continuous service up to 1500°F (816°C) and intermittent service up to 1600°F (871°C).

Resistance to Intergranular Corrosion: The titanium addition prevents the formation of chromium carbides at grain boundaries during welding and high-temperature exposure, preserving the alloy's inherent corrosion resistance.

Excellent Corrosion Resistance: Offers good resistance to a wide range of atmospheric environments and many corrosive media, similar to 304 stainless steel, but with enhanced stability.

Outstanding Formability and Weldability: Exhibits good ductility and can be readily formed and fabricated using standard methods. It is highly weldable, especially for heavy sections, without the risk of weld decay.

Durability and Long Service Life: Designed for demanding applications where both heat and corrosion are factors, ensuring reliability and reducing maintenance costs.

Typical Chemical Composition (Weight %)

| Element | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Chromium (Cr) | Nickel (Ni) | Titanium (Ti) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|

| % | 0.08 max | 2.0 max | 0.045 max | 0.030 max | 0.75 max | 17.0 - 19.0 | 9.0 - 12.0 | 5*(C) min | Balance |

Typical Mechanical Properties (Annealed Condition)

| Property | Tensile Strength | Yield Strength (0.2% Offset) | Elongation (% in 2") | Hardness (Brinell) | Hardness (Rockwell B) |

|---|---|---|---|---|---|

| Value | 75 ksi (515 MPa) min | 30 ksi (205 MPa) min | 40% min | 201 max | 92 max |

Applications

321 stainless steel plate is widely used in industries requiring stability against severe corrosion and heat:

Aerospace: Jet engine components, exhaust ducts, afterburners, and heat shields.

Chemical Processing: Vessels, piping, and heat exchangers exposed to corrosive chemicals at high temperatures.

Power Generation: Superheater tubes, boiler baffles, and other high-temperature pressure vessels.

Automotive: Exhaust systems, manifolds, and catalytic converter housings.

Petrochemical: Furnace parts, refinery piping, and flare stacks.

Food Processing: Equipment requiring repeated sterilization and high-temperature processing.

Pharmaceutical: Process vessels and piping systems.

Available Specifications & Forms

We supply 321/321H stainless steel plate in compliance with major international standards, including:

ASTM A240 / ASME SA-240

ASTM A167, ASTM A479

EN 1.4541

Available Sizes:

Thickness: From 0.5mm (0.02") to 100mm (4") and above.

Width: Up to 2000mm (78.7").

Length: Up to 6000mm (236") or as required.

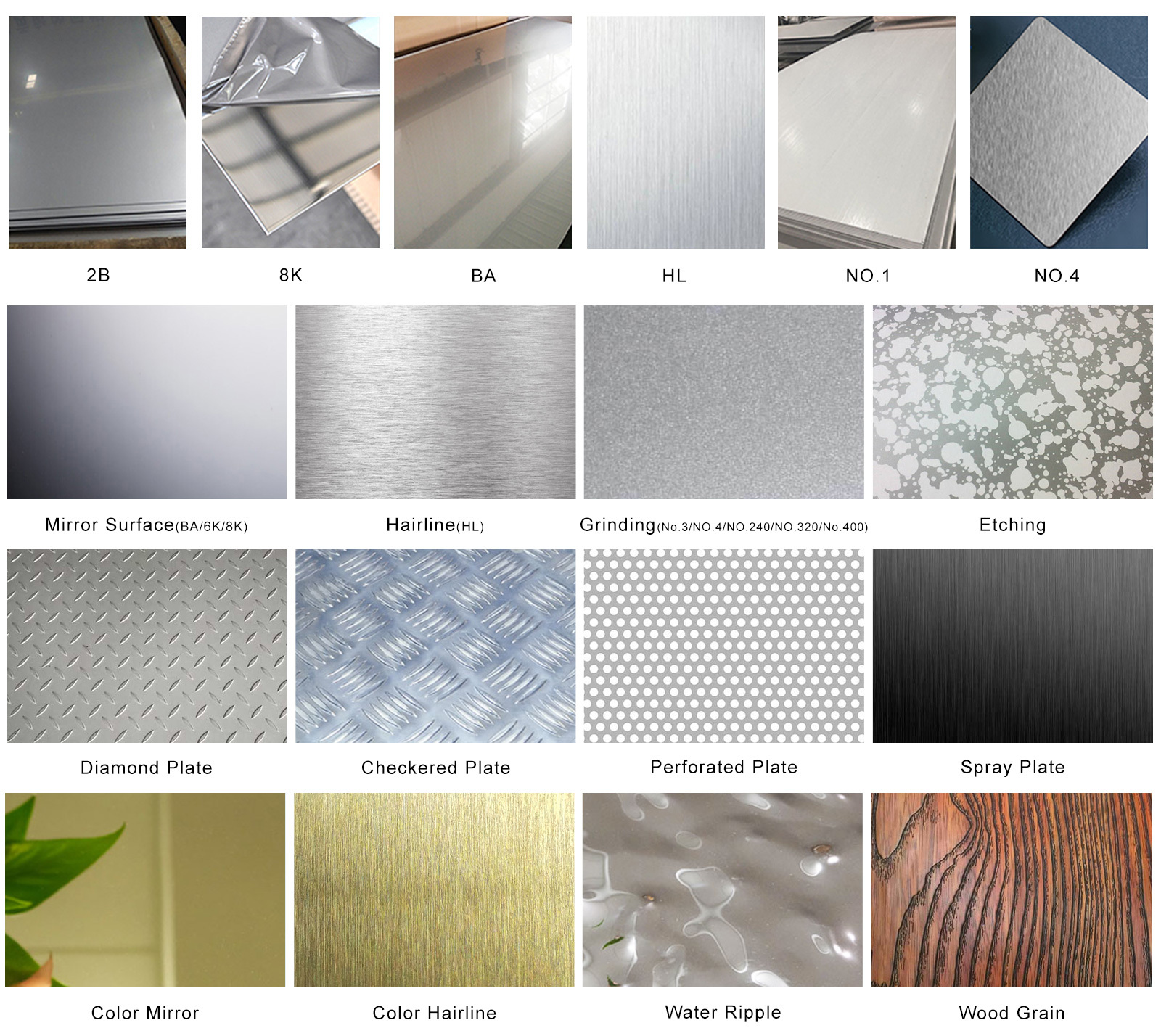

Surface Finishes:

No. 1 (Hot Rolled, Annealed & Pickled)

No. 2D (Cold Rolled, Dull)

No. 2B (Cold Rolled, Bright Annealed)

BA (Bright Annealed)

Polished Finishes (e.g., #4, #8)

Why Choose Our 321 Stainless Steel Plates?

Our products are manufactured to the highest quality standards, ensuring consistent chemistry, mechanical properties, and dimensional accuracy. We offer a full range of sizes and provide value-added processing services like cutting, leveling, and grinding to meet your precise fabrication needs.

Contact Us Today

For more technical information, a competitive quotation, or to discuss your specific application requirements, please contact our sales team. Let us provide you with the high-performance material solution you need.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Sign up for our newsletter

Copyright © 2024 Shandong Ruixiang Iron and Steel Group Co., Ltd. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.