904L Stainless steel plate (UNS N08904 / 1.4539) is a high-performance, austenitic stainless steel specifically engineered for exceptional resistance to a wide range of corrosive media. While part of the stainless steel family, 904L is considered a "super-austenitic" grade due to its significantly enhanced alloy composition, primarily the high levels of nickel, chromium, molybdenum, and copper.

This material is the ideal choice for applications where standard stainless steels like 304 or 316 are inadequate. It offers outstanding performance in sulfuric acid, phosphoric acid, and other aggressive environments, particularly those containing chlorides.

Product Name | |

Standard | JIS, AISI, ASTM, GB,DIN, EN, etc. |

Material | 904L |

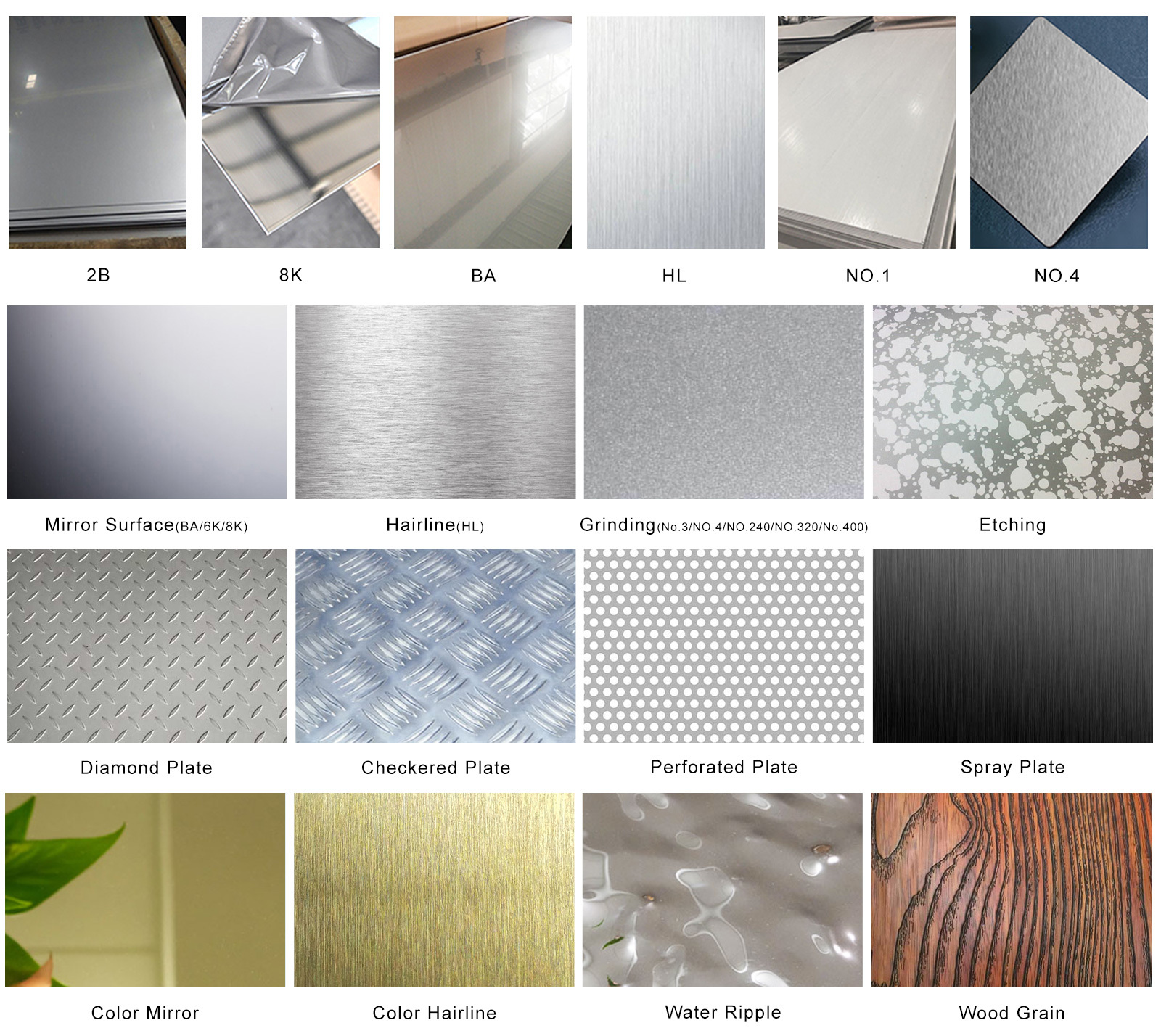

Surface | black painted, anti rust varnished, PE coated, anti rust oiled, galvanized, checkered, color coated |

Width | 1219mm, 50mm-2200mm, or as customer's requirement |

Length | 2438mm, 3m, 5.8m, 6m, 11.8m, 12m, or as customer's requirement |

Thickness | Cold rolled:0.1~3.0mm or customer's requirement |

Technical Methods | Hot Rolled, Cold rolled |

Packing | Standard Seaworthy Packing, according to customer required |

MOQ | 1 Ton, more quantity price will be lower |

Key Features & Advantages

Exceptional Corrosion Resistance: Excellently resistant to uniform attack from sulfuric acid, even in concentrated forms, and to pitting and crevice corrosion in chloride-bearing environments. The addition of copper enhances its resistance to sulfuric acid.

High Durability & Strength: Offers excellent mechanical properties and good structural integrity, even in demanding conditions.

Excellent Weldability: Can be readily welded using standard welding techniques, with welds that maintain good corrosion resistance.

Good Formability: Exhibits ductility and formability comparable to other austenitic stainless steels, allowing for fabrication into complex components.

Low Carbon Content: The low carbon content minimizes the risk of carbide precipitation during welding, preserving its corrosion resistance in the heat-affected zone.

Chemical Composition (Typical % Weight)

| Element | Percentage | Role |

|---|---|---|

| Chromium (Cr) | 19.0 - 23.0 | Provides basic corrosion resistance and passivation. |

| Nickel (Ni) | 23.0 - 28.0 | Enhances resistance to acids and maintains austenitic structure. |

| Molybdenum (Mo) | 4.0 - 5.0 | Drastically improves resistance to pitting and crevice corrosion. |

| Copper (Cu) | 1.0 - 2.0 | Key for resistance to sulfuric acid. |

| Manganese (Mn) | 2.00 max | |

| Silicon (Si) | 1.00 max | |

| Carbon (C) | 0.02 max | Low carbon prevents sensitization. |

| Phosphorus (P) | 0.045 max | |

| Sulfur (S) | 0.035 max | |

| Iron (Fe) | Balance |

Mechanical & Physical Properties (At Room Temperature)

| Property | Value |

|---|---|

| Tensile Strength | ≥ 490 MPa (71 ksi) |

| Yield Strength (0.2% Offset) | ≥ 220 MPa (32 ksi) |

| Elongation (in 50mm) | ≥ 35% |

| Hardness (Brinell) | ≤ 90 HB |

| Density | 7.95 g/cm³ (0.287 lb/in³) |

| Melting Range | 1300 - 1390 °C (2370 - 2530 °F) |

Typical Applications

904L plate is widely used across industries where corrosion is a critical concern:

Chemical Processing: Vessels, tanks, piping, and heat exchangers handling sulfuric, phosphoric, and acetic acids.

Pollution Control: Scrubbers, ducting, and chimney liners in flue gas desulfurization (FGD) systems.

Oil & Gas: Components for upstream and downstream processing, especially in sour gas environments.

Pharmaceutical Industry: Reaction vessels and piping where high purity and corrosion resistance are paramount.

Seawater Applications: Heat exchangers and piping systems utilizing seawater for cooling.

Pulp & Paper Industry: Digester and bleaching equipment.

Fabrication & Handling

Machining: 904L work-hardens rapidly. It requires powerful machinery, rigid set-ups, positive feeds, and sharp tools made of high-speed steel or carbide.

Welding: Common processes include TIG (GTAW) and MIG (GMAW). Welding rods or electrodes such as ER385 or ENiCrMo-3 are recommended.

Heat Treatment: Solution annealing is performed at 1090-1170°C (1990-2140°F) followed by rapid quenching in water.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Sign up for our newsletter

Copyright © 2024 Shandong Ruixiang Iron and Steel Group Co., Ltd. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.